About ITT Goulds Pumps // ANSI B73.1

VIKING GEAR PUMP

Howden Turbo

SANDPIPER® : AIR-OPERATED DOUBLE DIAPHRAGM PUMP

Centrifugal Pump - Commercial Water

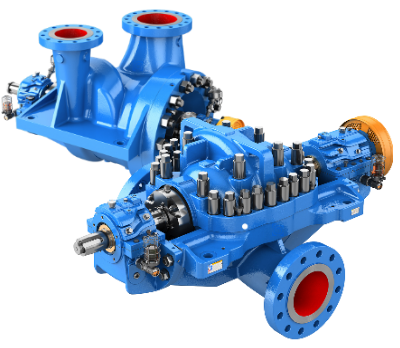

About ITT Goulds Pumps // Between Bearing

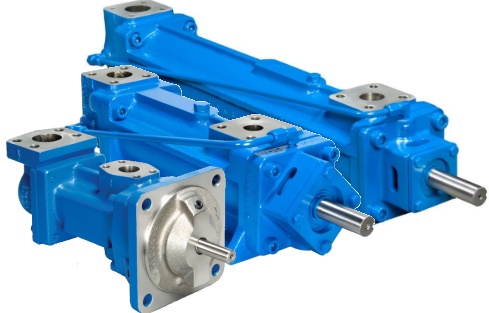

IMO – Three Screw

Wright Flow Technologies

Travaini Vacuum Pump

OMG API Metering Pump

Jesco Dosing pumps

ITT Industrial Process // API610 Pump

ITT Goulds Pumps // Vertical Suspended Shaft

HV turbo Compressors

Kansai Automation Level Meter // Level Switch // Flow Meter // Other Analyzer

LC PD Meter // Turbine Meter // Batch Controller // Vane Pump by 'Corken'

IOT // i-ALERT3 Wireless Sensor//Machine Monitoring

IOT // Liquid Controls LCR.iQ // Register Networking

Looking for a price?? Register with us and gain access to our shopping centre to have a look into our stocks or sent us enquiry

SHOP NOW